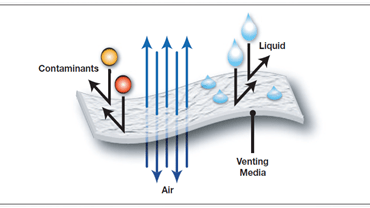

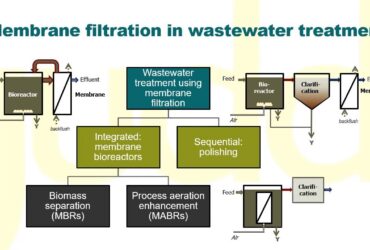

Membrane filters may either remove the particles polluting the water by acting as a barrier between the water and the pollutants, or they can remove the contaminants themselves. To carry out their respective filtering processes, reverse osmosis, ultrafiltration, and nanofiltration each use a membrane. There are a variety of arrangements for filtration membranes.Some membranes use the process of reverse osmosis (RO), ultrafiltration (UF), and nanofiltration (NF). The membrane filtration process is approached somewhat differently by each of these entities.

How does a filter that uses a membrane work?

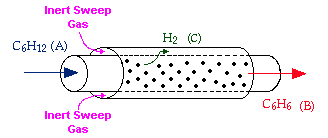

In the process of reverse osmosis, pressure is applied to a membrane that is only partially permeable, allowing water molecules to flow through while simultaneously flushing dissolved inorganic substances down the drain. Therefore, it creates two distinct paths for the water to go.

The water is not separated by ultrafiltration in the same way that it is with a reverse osmosis membrane. In reality, all that it is is a filter for minimal particulate matter or dirt. Particles smaller than 0.025 microns removed by mechanical filtering are too large to pass through the filtration membranes. The technique of nanofiltration membranes works very similarly to reverse osmosis; the only difference is that the filtration is not nearly as refined.

Osmosis in reverse and a membrane that does ultrafiltration?

Reverse osmosis and ultrafiltration vary quite a deal. In contrast to ultrafiltration, which can only remove solids and particles from the water, reverse osmosis may also remove dissolved minerals from the water. It is possible to remove dissolved inorganic minerals via reverse osmosis, and these minerals will be able to flow through the UF membrane.

What are the components that makeup membrane filters?

Many different kinds of materials are used in the production of membranes. Thin-film composite membranes are the common name given to them when discussing the process of reverse osmosis. In the past, the membrane used in reverse osmosis was constructed out of cellulose triacetate, also known as CTA. CTA membranes are no longer sold.

RO membranes of this period had a limited pH tolerance and were the initial generation of the technology. They did not produce a significant amount of water per unit of area. Because a thin-film membrane allows a RO system to create a high quantity of water in a relatively small amount of space, it is now feasible to house more extensive membranes in physically more miniature housings. The design of membranes used in reverse osmosis was wholly altered. The UF employs the same general substance, but its formulation is somewhat different.

When should a membrane filter be replaced, and how frequently?

When using a reverse osmosis membrane, replacement should be performed every two to three years, depending on the quality of the water. As the RO membrane rejects additional minerals, some of the minerals previously in solution begin to precipitate out of solution and clog the surface area of the membrane.

If you feed the RO system with softened water, the membrane could endure for five years if you regularly change the filters in the system. However, this only applies if you do not use hard water. The ultrafiltration membrane should be replaced every other year when used in a point-of-use (POU) application. As they filter, UF membranes gather the pollutants passing through them.

How exactly does one go about cleaning a membrane filter?

A point-of-use (POU) system in a domestic setting does not need to clean the filter membrane. To flush the membrane or clean it, chemicals must be used to remove some of the scale or particles that are clogging up the membrane. It is not as cost-effective to try to clean or flush the membrane as to replace it every few years. Before using the membrane, you must always ensure it has been thoroughly washed.

What are the steps involved in flushing a filter membrane?

The ultrafiltration (UF) membrane technology is not a separation but a flow-through membrane. To begin flushing the filtration membranes at start-up, just remove all of the air trapped within it during manufacture. Because these membranes are created and then dried, cleaning a reverse osmosis system is essential before starting it up. This helps the membranes to re-saturate. Before employing a point-of-use (POU) system, the water in two or three of the system’s tanks should be allowed to drain completely before the system is activated.