Although it is widely accepted that membrane reactors offer several benefits over other technologies for treating wastewater, this does not mean that they are always the best option.

The fact that the biological solids, also known as mixed liquor or sludge, are kept entirely within the bioreactor is one of the most important benefits of the membrane bioreactor method. This indicates that the bioreactor’s solids retention time, also known as SRT, may be regulated independently from the hydraulic retention time (HRT).

This is different from the CAS process, in which the flocculant solids that make up the biomass have to be allowed to grow in size to the point where they can be settled out in the secondary clarifier. In the CAS process, the flocsmust be allowed to rise to the point where they can be settled. Because the floc size and thus its settlability are related to the HRT, the HRT and the SRT are therefore connected in a CAS. Increasing the HRT increases the length of time the flocs have to develop in the bioreactor, enhancing their settleability.

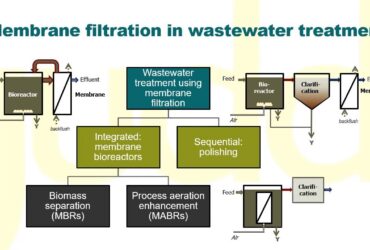

The wastewater treatment

In biological wastewater treatment, the SRT is an important determining factor. An increase in the SRT, also known as the amount of time that the biological solids are kept in the bioreactor, increases the concentration of the biological solids.

The effluent of a very high grade

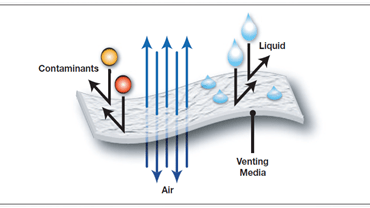

Compared to the CAS procedure, the treated effluent has an exceptionally high level of transparency and a much lower concentration of pathogens thanks to the tiny pore size of the membrane, which is less than 0.5 micrometers.

The effluent produced by MBR procedures is considerably purified and disinfected. Its quality is good enough that it may either be released into sensitive receiving bodies or recovered for urban irrigation, utility purposes, or toilet flushing. Additionally, it is of a quality that allows it to be fed straight into a process that utilizes reverse osmosis.

Light on the ground

There will be an effect on the plant’s footprint due to the decision to keep the solids in the reactor and boost the SRT to produce more significant biomass solids concentrations. Because of the higher concentrations, the same amount of total mass of solids may be held in a smaller container, which results in a smaller footprint.

Better biotreatment

In conclusion, more extended solids retention periodstend to give superior biotreatment. The environment fosters the growth of microorganisms with a slower rate of reproduction, particularly nitrifiers. MBRs are particularly useful for the process known as “nitrification,” which refers to the biological elimination of ammonia.

MBR technology is increasingly becoming the choice for water and wastewater applications where high-quality treated water is required, or space is limited. Even though MBR technology is not always the best solution for treating wastewater — for example, it can sometimes be more expensive than other solutions — MBRs are increasingly becoming the technology of choice for applications.

MBRs are currently being used in the market, and growth rates of up to 15% are routinely reported in various market assessments. Several plants with a capacity of more than 100 MLD (stated as peak daily flow) have recently been erected, which contributes to the growing sense that confidence in the method is continuing to develop despite the ongoing expansion of both the number and size of reference installations.

Conditions of the boundary

In treating biologically degradable wastewater flows, membrane reactors may be used. Specific harmful partial discharges, for example, those from the chemical sector, cannot be used unless effluents from other processes suitably dilute them.

The quality of the influent has a significant impact on the quality of the permeate that the MBR produces. Before the wastewater is introduced to the MBR, any items that might be disruptive (such as long fibers or sharp particles), which could clog or damage the membrane, must be removed. A standard sieve is often all that is required to remove any undissolved materials effectively (gauze width 0.5 – 2 mm). The membranes are also susceptible to harm from dissolved chemicals, particularly those with high calcium concentrations and aluminum salts.

Effectiveness

MBR technology works to remove organic compounds (COD and BOD), suspended matter, nutrients (nitrogen and phosphorus), and bio-accumulative or bio-degradable micro contaminants in the same manner as traditional active sludge systems do.

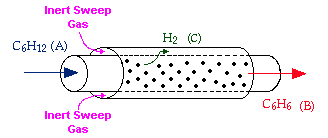

The biological conversion mechanisms are the same for active sludge systems for COD removal, nitrifying active sludge, and nitrifying/denitrifying active sludge. These systems remove COD from wastewater by nitrifying and denitrifying active sludge.The existence of membrane reactors makes it possible to ultimately retain all biological content while simultaneously eliminating all suspended materials.