Description

OXYMO’s Hollow fiber membrane production machine can be used to produce hollow fiber ultrafiltration membranes and is suitable for the processing and production of polyvinylidene fluoride (PVDF), PVC, PAN, PES and other polymer material.

Service

- Equipment installation guidance and commissioning

- Hollow fiber membrane spinning production technology and training

- Hollow fiber membrane spinning machine equipment user manual, repair, maintenance technology and training

- Ultrafiltration membrane housing potting technology and training

- Hollow fiber membrane spinning production formula and process training

Features

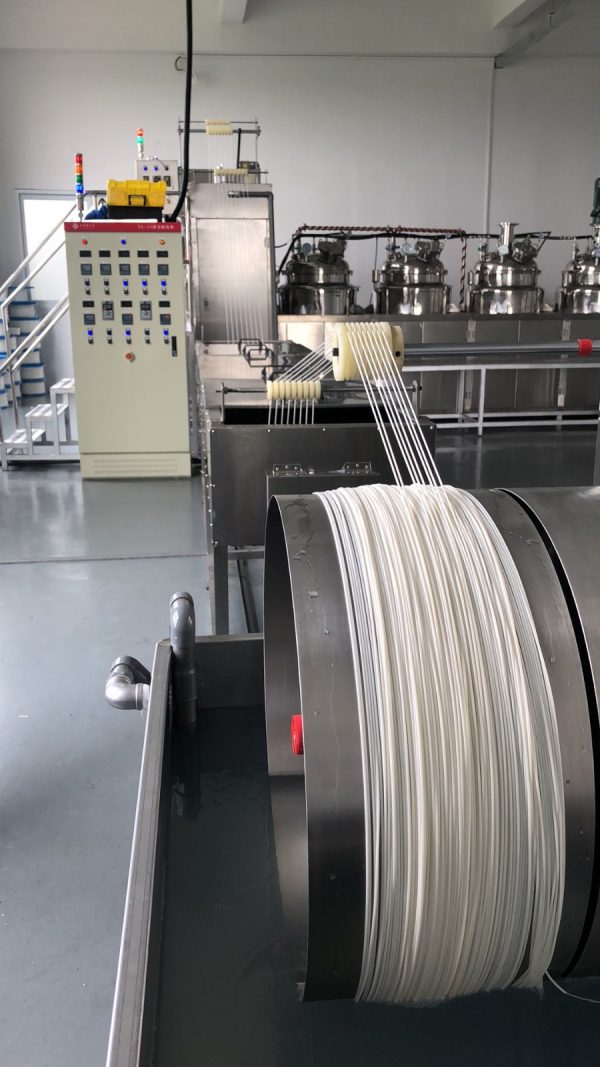

Main body of spinning machine

- The spinning machine integrates a kettle, metering pump, filter, spinneret and control system, which facilitates the feeding, mixing and dissolving, defoaming and fiber discharging of the casting liquid, and can be visually inspected and operated easily.

- Coagulation bath

The coagulation bath includes a bath tank, fast wire guide components and ancillary control systems to complete the spinning

drafting filter hole replacement and skin layer forming of the casting solution.

- Winding device

The winding device is mainly composed of a wire winding roller, a guide wheel, a counting device, a rinsing tank and ancillary control systems, which facilitates the collection of drafted membrane fiber

Reviews

There are no reviews yet.