Ultrafiltration water treatment is a form of membrane filtration similar to reverse osmosis by

separating the solid particles from the sources that influence the liquid. This process is between

microfiltration and nanofiltration in terms of particle size removal. They are used as primary

filters for other treatment processes or as tertiary scrubbing filters in drinking water and

wastewater treatment.

What is the application of the ultrafiltration water treatment?

UF can be used for the removal of particles and macromolecules from raw water to produce

drinking water. It is used to replace the existing secondary system and tertiary filtration. When

treating water with high suspended solids, UF is often incorporated into the process using

primary (screening, flotation, and filtration) and secondary treatment as the pre-treatment step.

Ultrafiltration is more popular than conventional treatments. For the following reasons:

- No chemicals are required (besides cleaning)

- Consistent product quality regardless of feed quality.

- Compact factory size

- Exceeding water quality standards Kills 90-100% of germs

When water recycling is easy, however, when more intensive processing is required, industry

standard procedures include the use of UF, which means the physical removal of solids from

water by passing a semi-permeable membrane. The use of ultrafiltration water treatment is

mainly captured by the filter and discarded.

Recycled water can also be used for many industrial purposes, including filling of boiler or

cooling tower feed water, adjusting pH, and washing equipment. Some of the right platforms are

vehicles fire protection systems and washing water in the process or processed water for the

production line in the manufacturing industry, toilet flushing, dust control, construction

activities, and concrete mix.

What are the benefits of ultrafiltration water treatment?

Zero energy requirements:

The ultrafiltration water treatment requires no electricity to work. Water can be filtered using

natural pressure. No more worrying about power outages or paying electricity bills. Choose a

non-energy water purification process.

Eliminate viruses and bacteria:

Ultrafiltration removes particles from the water by forcing them through the membrane. So it

doesn't just destroy all bacteria and viruses but also removes their eggs from the water to make

sure the water is pure and safe.

Deep cleaning:

Ultrafiltration systems can be used to purify dirty muddy water. It can easily remove solid

particles and bacteria from dirty water compared to other purification systems. In addition,

ultrafiltration membranes can filter the dirtiest water, making it suitable for drinking.

The purest form of drinking water is guaranteed:

The ultrafiltration system will never fail to produce drinking water because the ultrafiltration

membrane is very tough, thus not allowing small or large particles to pass through. This process

is unmatched with RO membranes.

Low maintenance and high efficiency:

Ultrafiltration System does not require complicated maintenance procedures and can be in

excellent working condition for many years. The manual washing device in these types of filters

removes all blocked bacteria and mud to keep the air purifier in its optimal state for at least

eleven years.

Excellent purification:

In addition to the system, after ultrafiltration, most water purification processes use chlorine

treatment to disinfect and separate pathogens from the water. But this traditional method cannot

remove eggs (cysts). In contrast, the Ultrafiltration System removes chlorine-resistant eggs

(Cysts) of gastroenteritis parasites such as cryptosporidiosis and giardiasis, and amoeba to ensure

pure drinking water.

What are the membrane types in ultrafiltration water treatment?

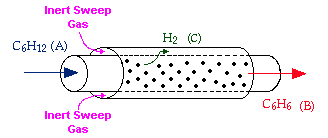

Polymer:

These membranes are made from polymer materials such as polysulfone, propylene, cellulose

acetate, and polylactic acid. Polymer membranes are more commonly used because of their

efficiency and cost-effectiveness.

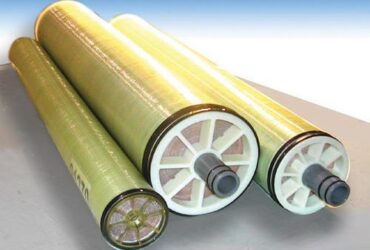

Ceramic:

There are various types of materials for ceramic membranes, from aluminum oxide and silicon

carbide to titanium dioxide and zirconium dioxide. It is known for its flexibility when exposed to

high temperatures or corrosive chemicals. But it's also much more expensive.

What are the distinctive features of ultrafiltration water treatment?

The top-notch features of the ultrafiltration water treatment are given by,

- Modular design for quick installation

- High energy saving system

- Best fractionation output among competing products.

- Excellent quality products

- Long-lasting membrane and low fouling

- Low maintenance requirements

- Provide advanced monitoring and control system

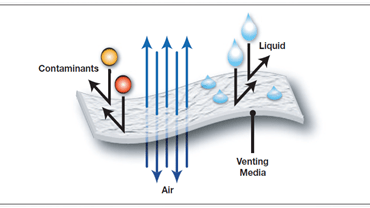

- Top-of-the-line equipmentUltrafiltration is a separation technique rather than using membranes with pore sizes ranging

from .01 to .001 microns. This method is used to remove high molecular weight impurities. In

addition, it can remove organic and inorganic polymer molecules and colloidal materials.