Over the past decade, the PTFE membrane has gained more prominence and gives more benefits.

When it comes to using, there may be various discussions and deliberation. The ptfe membrane

will become chemically inert and has been used in multiple membrane separation processes,

including membrane distillation, oil-water separation, and then also gas-solid separation. To

date, the plate sheet and hollow fiber have in the most common form of the PTFE membrane.

It is mainly developed or produced by various spinning, stretching, and pore-forming techniques.

In order to achieve enhanced performance for the targeted application, multiple modification

methods like wet chemical, plasma, atomic layer deposition, irradiation, and then high-

temperature melting is employed to improve the properties of the PTFE membrane. Thus, you

need to know more about it, and you must keep reading the article and gain various data.

How does the PTFE membrane work?

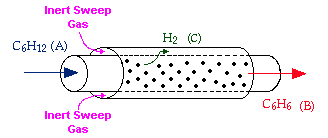

Let’s move closer to like how the ptfe membrane works. In case you zoom on to the PTFE

membrane that will be made out of the tiny microscope holes like Swiss cheese. Thus, the holes

are larger enough to enter the air molecules and then vapors in order to pass through and then

small enough to inhibit. In that, even the smallest dust particles get through it. Due to the

membrane holds and the dust on the bag's surface, particles will not get embedded into the giant

fibers,Thus, PTFE membrane bags are worn out

before plugging up and usually lasting as a standard bag.

Various benefits of the PTFE membrane

With double the lifespan, costly changes out and then plan shutdown are cut in half to reduce the

maintenance cost and cost of plant production. Of course, bags are not gradually plugging up

over time, and then it will give additional benefits by providing consistent airflow or suction

from your dust collection system. This is why small pores size, the ptfe membrane bags are

raised to eight times more efficient than the standard filter bag. It means to cut out the collector

emission by up to 800 percent.

Get the additional advantages of the PTFE membrane.

It may have more advantages than the PTFE membrane bags, and they will clean easier due to

their slick surface. It means less bag pulsing and less wear and tears in the bag. In addition, less

wear in the diaphragms and then solenoid valves. This also means the system may use less

comprised air, which will result in reduced energy cost, which will be one of the main benefits to

the people. In addition, it may also improve the performance during higher moisture levels or

sticky dust present.

PTFE membrane can be joined into any bag media related to the standard bag and in almost all

applications. Well, there is a cost to add the membrane, and the extra cost will quickly pay for

itself. In addition, it will provide long-term life; lessen maintenance costs, less wear, and tear,

and lower emissions. These are the various other topmost advantages available on the PTFE

membrane.

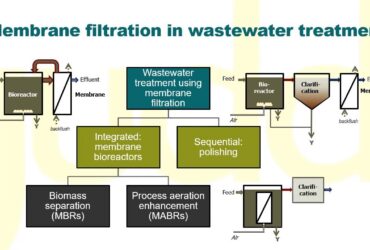

Various applications of PTFE membrane

The ptfe membrane is highly used in various other industries, and then that are listed below.

Electrical appliances: The PTFE is one of the topmost best insulators, as you know. The thick

wall close tolerance extrudes the tubing into the PTFE shape as of choice, where the machining

and then drilling long length. It can be machined onto the stand-off insulators.

Petrochemical and chemical processing: It is the material for the choice of gaskets, pump

interior, vessel lining, rings, seals, spacers, dip tubes, and suitable drilling components. This is

why it is corrosion resistant and then chemically inert.

Laboratory application: The PTFE tubing, piping, and vessels are used in various laboratory

wares. This is because of the chemical resistance, inertness, and no contamination after the

surface.

Food and pharmaceutical industries: The virgin PTFE has been approved by the FDA in order to

use in the food, cosmetics, beverages, and pharmaceutical industries. It can withstand high

temperatures.

Now you may get more information about the PTFE membrane and its various primary usage

and applicants.