Description

Membrane distillation (MD) is a membrane separation process that uses a hydrophobic microporous membrane with the vapor pressure difference on both sides of the membrane as the driving force for mass transfer. It can be used for water distilling and desalination to remove volatile substances from aqueous solutions. For example, when aqueous solutions of different temperatures are separated by a hydrophobic microporous membrane, due to the hydrophobicity of the membrane, the aqueous solutions on both sides cannot pass through the pores of the membrane and enter the other side, but due to the high water vapor pressure at the interface between the aqueous solution on the warm side and the membrane On the cold side, water vapor will enter the cold side from the warm side through the pores of the membrane and condense. This is very similar to the evaporation, mass transfer, and condensation processes in conventional distillation, so it is called the PTFE membrane Distillation process.

Membrane distillation technology has many advantages:

(1) The membrane distillation process is carried out under normal pressure, the equipment is simple, the operation is convenient, and it is possible to realize it in areas with weak technical strength;

(2) The process can handle extremely high concentrations If the solute is easy to crystallize, the solution can be concentrated to a supersaturated state and the membrane distillation crystallization phenomenon occurs. It is the only membrane process that can directly separate the crystalline product from the solution;

(3) The membrane distillation module is easy to design In the form of latent heat recovery, it has the flexibility to form a large-scale production system with highly efficient small membrane modules;

PTFE Membrane Distillation Fiber

|

Specification |

Fiber #1 |

Fiber #2 |

| Membrane Material | PTFE | PTFE |

| Fiber Inner Diameter(mm) | 0.52 | 0.75 |

| Fiber Outer Diameter(mm) | 1 | 1.75 |

| Porosity (%) | 45 | 44 |

| Water Penetration Pressure (bar) | >4.5 | >3.0 |

| Flux(L/m2.h) | 3-8 | 3-8 |

PTFE Membrane distillation Module

| Model

Specification |

MD4040S |

MD4040B |

MD6040S |

MD6040B |

| Effective Area (m2) | 10 | 6 | 28 | 20 |

| Module Flux(L/h) | 30-80 | 18-64 | 84-224 | 60-160 |

| Membrane Material | PTFE 1.0mm | PTFE 1.57mm | PTFE 1.0mm | PTFE 1.57mm |

| Housing Material | CPVC | CPVC | ||

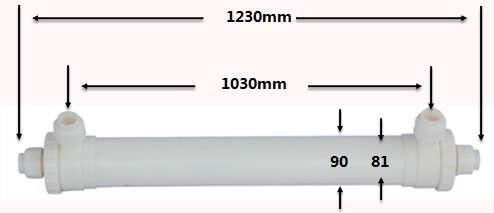

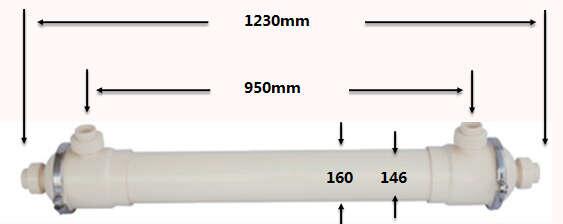

| Module Dimension | ф90-1230mm | ф160-1230mm | ||

| Port Size (mm) | DN25 | DN40 | ||

Advantages

(1) The membrane distillation process is carried out under normal pressure, the equipment is simple, the operation is convenient, and it is possible to realize it in areas with weak technical strength;

(2) The process can handle extremely high concentrations If the solute is easy to crystallize, the solution can be concentrated to a supersaturated state and the membrane distillation crystallization phenomenon occurs. It is the only membrane process that can directly separate the crystalline product from the solution;

(3) The membrane distillation module is easy to design In the form of latent heat recovery, it has the flexibility to form a large-scale production system with highly efficient small membrane modules;

Why We Do

Membrane water treatment technology has the characteristics of high efficiency and energy saving. To some certain extent, the popularization and application coverage of membrane separation technology reflects the level of energy use and environmental protection of a country and region. It is also a guarantee means for the sustainable development of society. Therefore, The strategic position of membrane separation technology is very prominent.

The key point to membrane water treatment is the microporous structure and surface properties of the membrane material. Scientists around the world proceed from the selection of materials and the optimization of the membrane-making process in order to prepare a membrane separation materials with excellent performance.

Accessing a membrane have a good practical value should depend on the following few points:

High retention rate and high water permeability rate;

Strong resistance to physical, chemical and microbial attack;

Flexible and sufficient mechanical strength;

Resistant to high temperature

Excellent anti-pollution;

Good resistance to chlorine and other oxides;

Long service life and withstand wide range of pH value;

Low operating pressure

Easy to store and transport;

Convenient preparation and industrialized production;

Dry and wet reversible.

Obtaining membrane separation materials with excellent separation selectivity and higher permeability has always been the goal pursued by membrane scientists and engineers. Through research on hollow fiber membranes from the selection of membrane-forming materials, optimization of process parameters, surface post-treatment, and design of membrane modules in scientific research institutions all over the world in recent decades, the overall performance of hollow fiber ultrafiltration membranes and microfiltration membranes has been improved greatly.

Recently, the high-end ultra-hydrophilic and excellent membrane pore microstructure separation membranes are mainly produced by few international famous companies. Including XP series hydrophilic hollow fiber ultrafiltration membranes from DuPont -Dow, HYDRAcap series hydrophilic hollow fiber ultrafiltration membranes produced by Nitto/hydranautics, DICP series polyvinylidene fluoride hydrophilic ultrafiltration membrane from Toray. Targa series hollow ultrafiltration membrane produced by Koch and hydrophilic hollow fiber ultrafiltration membrane from SUEZ (GE). Therefore, these few international well-known brands firmly occupy the high-end market of ultrafiltration membranes.

In recent years, Chinese ultrafiltration and microfiltration membranes have also improved to a certain extent in terms of material types, membrane structure and performance etc. However, Chinese companies are still lacking a high-performance ultra / micro-membrane for water treatment with excellent comprehensive properties such as super-hydrophilicity, high anti-pollution, high strength, high throughput, low membrane pressure and long-term service stability. These high-end membranes still rely heavily on foreign brands. This situation greatly limits Chinese membrane’s service lifespan and application fields.

What We Have Done

Aiming at the shortcomings of existing technology, hydroblue have developed a high performance ultrafiltration membrane with properties of gradient pore microstructure, super-hydrophilicity, high anti-pollution, high strength, high flux, low trans-membrane pressure and long-term service stability. All comprehensive performance has reached the level of these international well-known companies in Europe, USA and Japan.

the micronano beads network structure (Figure1) is gradually increase from the outer surface to the inner surface along the radial section of the hollow fiber membrane. this network structure can significantly reduce the water permeation resistance, thereby significantly increasing water flux.

Reviews

There are no reviews yet.