Description

Product Specification

|

A、Membrane fiber Spec |

|||

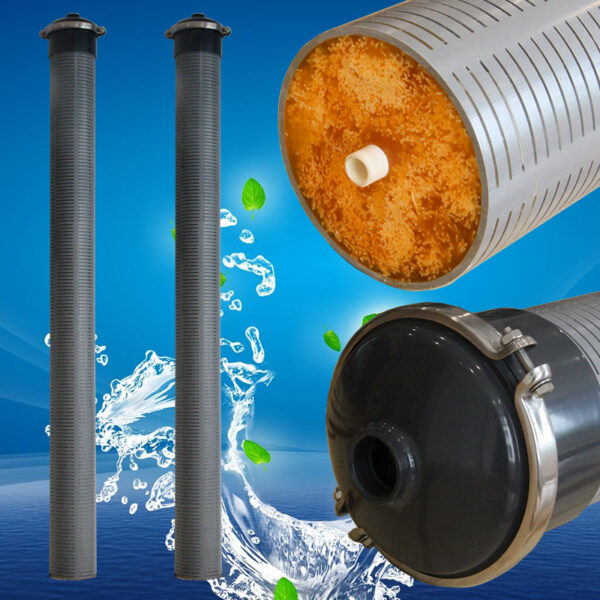

| Membrane material | PVDF | Membrane form | Outside-In hollow fiber membrane |

| Outer/Inner Diameter | 1.0/2.2mm | Nominal Pore size | 0.04μm |

| Breaking Strength | >200N | ||

|

B. Module Spec |

|||

| Membrane housing material | UPVC | End Cap material | UPVC |

| Seal Material | EPDM rubber | Potting Material | Epoxy Resin |

| Nominal Area | 40m2 | Size | φ160xL1987mm |

| Dry Weight | 15kg | Wet Weight | 25kg |

|

C、Using condition |

|||

| Operation way | Negative pressure suction filtration | Design Flux | 20-55L/h |

| Operating Temperature | 5-45℃ | Operating pH Range | 2-11(when cleaning 1-12) |

| Max TMP Range | -80KPa | Max Backwash Pressure | 150KPa |

| Backwash flux | 1.5-4.0m3/hr | Air wash flow | ≤2.5m3/hr |

|

D. Permeate water quality |

|||

| Permeate Turbidity | ≤0.1NTU | Permeate SDI15 | ≤3 |

| Coliform | Not detected | Total number of colonies | Not detected |

Advantages

1. Greatly improve the recycling rate, reduce waste water discharge, and reduce up to 30%;

2. Reduce pressure and reduce energy consumption, up to 35%;

3. Reduce cleaning frequency and chemical cost;

4. Higher water production efficiency and lower initial investment:

5. Ultra-high flux, the same pressure difference flux can increase up to 40%

6. Higher water production efficiency, fewer ultrafiltration membrane elements

7. The water production efficiency of the same land area can be increased by up to 120%

8. Greatly reduce downtime and cleaning time

Who we are

Hydro Blue Membrane Technology has accumulated rich experience in the transformation of sand filter into membrane filtration process. The original sand filter can be transformed into membrane tank, and the membrane method can be transformed without increasing the land occupation and investment of civil construction. Membrane filtration has become a powerful technology and equipment for municipal tap water, reclaimed water reuse and other industries for upgrading and transformation, as well as industrial complex water supply and reverse osmosis pre-filtration.

Reviews

There are no reviews yet.