Description

The pore size of the outer and inner surface of gravity ultra-low pressure hollow fiber membranes can be precisely controlled, the pore size control range is usually 0.05-0.2 µm.

|

ITEM |

Ultra-low pressure ultrafiltration membrane | |

| Type A (1K) | Type B (2K) | |

| Outer pore size | 0.05 µm | 0.1 µm |

| Inner pore size | 0.5 µm | 1 µm |

| Nominal pore size | 0.05 µm | 0.1 µm |

| Capillary Diameter | ID/OD = 0.75/1.25mm | ID/OD = 0.3/0.45mm |

| Flux (25°C, 0.1Mpa) | 1000 L/m2.h | 2000L/m2.h |

| Material | Solid PES, PSF | |

| Porosity | 70-75% | |

| Application | Gravity Filter Tower/Tank

Home filter etc. |

Filter Bottle, Filter Straw, filter pot, home filter etc. |

Techinical Advantages (PES,PSF)

Ordered Microporous Structure Membrane

It has reached and partially surpassed similar products from international brands .

“Zero pressure” type PES/PSF hollow fiber membrane is a “super hydrophilic, pressureless / ultra-low pressure, gradient microporous structure, ultra-high-throughput” drinking water post-treatment polymer membrane; The production process and method of the low-pressure membrane are fully carried out according to the high-end precision integrated technology of the highly safe hemodialysis membrane (artificial kidney). The organic leachables of polymer membrane meet the strictly high medical standards.

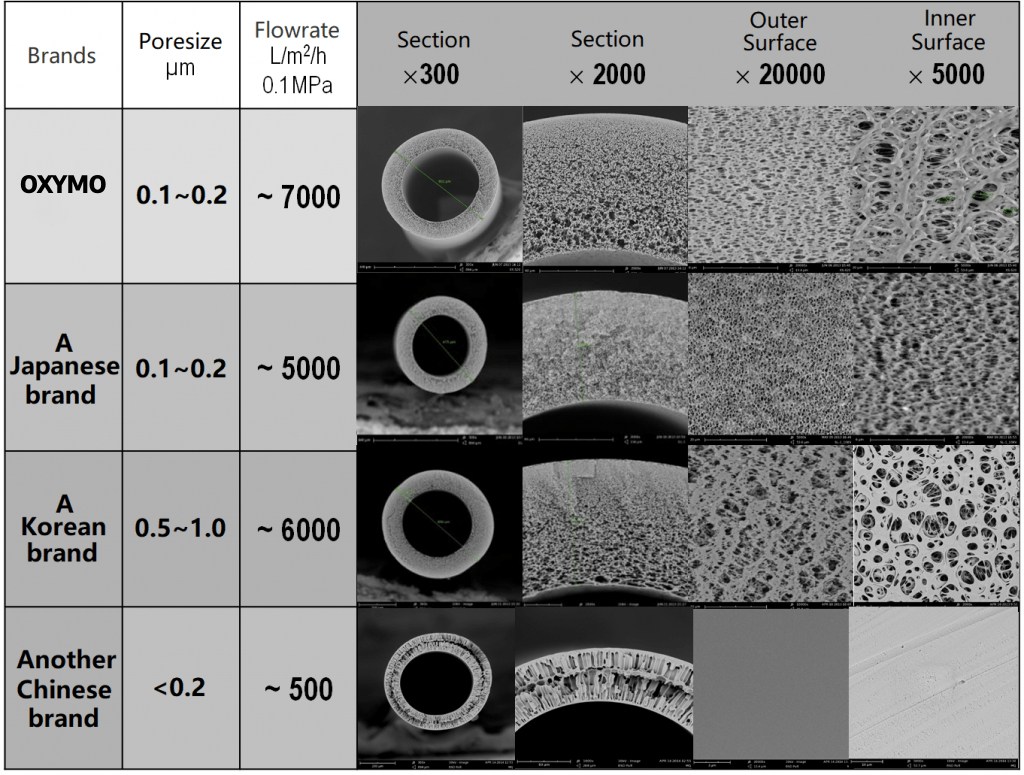

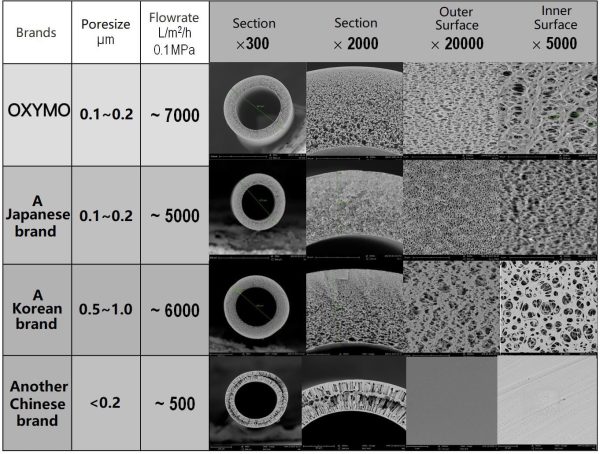

Its microstructure, water flux and safety performance have reached the level of similar products from international brands, Even part of the performance have exceeded the international level (Figure 2), And far ahead of other domestic similar membrane products.

Comparison With Other Brands

Super-Hydrophilic, Pressureless Self-Osmosis

The water contact angle on the surface of an ordinary commercial polymer membrane is basically maintained above 60degree. Accordingly, Water droplets on the surface of the super-hydrophilic polymer membrane can quickly penetrate into the inside of the membrane, and the water contact angle value drops to ZERO instantly. “Zero-pressure” type polysulfone hollow fiber membrane can reach 300 L / m2h (25°C) without external pressure drive.

The third-party authoritative inspection by the “National Oceanic Administration Tianjin Desalination and Comprehensive Utilization Testing Center” designated by the Ministry of Science and Technology and the Membrane Industry Association, hydroblue’s super-low pressure membrane water contact angle is ZERO.

High Filtration Precision

The gravity ultrafiltration membrane has a filtration accuracy of 0.05 micron (which is equivalent to one in ten-thousand of diameter of hair). all rust, colloids, algae, suspended matter, and sediment and 99.99% bacteria and microbes will be removed. (The average diameter of bacteria is 0.5 micron or more).

Excellent Anti-Pollution

The membrane cross-section has a gradient microporous structure, which makes the contaminants difficult to enter the membrane cross-section and basically stays on the outer surface of the membrane’s dense separation layer. The formed membrane pollution is reversible, contaminants are easily eluted from the membrane surface, achieving efficient membrane regeneration, repeated use, and increased service life.

The surface of the super-hydrophilic membrane is easy to form a highly anti-fouling hydration layer, which has good anti-microbial pollution ability, where bacteria and other microorganisms are not easy to reproduce on the surface of the hydrophilic membrane; and the super-hydrophilic membrane material is easy to clean and regenerate, and high recovery of flow rate, it is reusable.

Safety Membrane Material (PSF)

PSF raw material source from international famous brands Solvay and BASF only, which is a widely used biomedical material for hemodialysis membrane. The max organic leachables (COD) less than 2ppm. Polysulfone have excellent oxidation resistance, acid and alkali resistance, and biological inertia; especially for chlorine from municipal water. Polysulfone can still maintain excellent chlorine resistance and long-term stability. Non-toxic,non-degradable and no harmful chemicals are produced.

Reviews

There are no reviews yet.