Description

Product Specificatio

| ITEM |

SPECIFICATION |

| Dimension | Diameter: Ф90~ф400Length: 500~1000mm |

| Housing material | ABS + UPVC |

| Filter media | PP Foam + ACF+ UF membrane |

| Membrane material | Super hydrophilic PES/PS hollow fiber membrane |

| Effective area | 40~50m2 |

| Diameter of capillary | ID/OD = 0.75/1.25mm |

| Nominal pore size | 0.1~0.05 micron |

| Initial flow rate (30°C) per tap | ~600L/h ( at ~1.0m water level)

~450L/h ( at ~0.65m water level) |

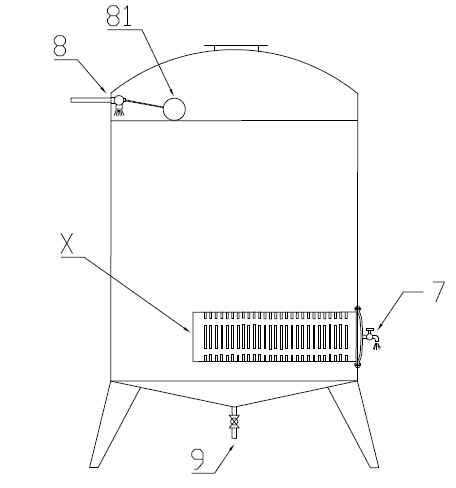

| Water Tank | PE Tank, water level 1.5~2m is the best |

| Module lifespan | Recommend 1~2years depend on feed water quality |

Technology Background

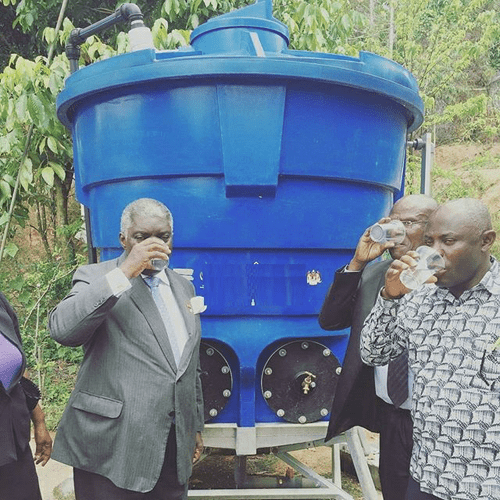

Due to the influence of human activities, surface water, groundwater and rainwater are mostly contaminated with different degrees of water, can not be directly consumed without deep purification treatment, high-quality natural water sources can not be sought. Especially in extreme harsh environments (such as plateau, high cold, high salt, high humidity or some sudden situations), people often can only take water in place, and most of these water sources exist in the total number of bacterial colonies, algae, worm eggs, microorganisms and other water quality problems, seriously threatening the health of the masses. In addition, the water problem is also a long-term needs of our military personnel to face a prominent problem, troops in the cross-regional mission, often to quickly assemble a large number of personnel, and after leaving the camp, a large number of people can drink a very limited water source. For example, in the 2014 earthquake in Ludian, Yunnan Province, there was a situation where disaster relief officers and soldiers could only boil bubble noodles with murky water. Therefore, for less-developed areas without electricity supply, poor economic conditions and low cost requirements, or in the special environment of the wild, it is necessary to develop water purification equipment that does not require electricity supply to solve the health and safety problems of emergency drinking water.

How It Work

The purpose of the technology is to overcome the defects that existing water purification devices require electrical energy supply and cannot filter water sources for long periods of time in outdoor environments.

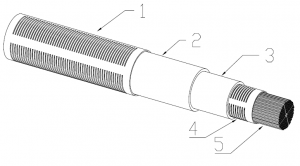

To achieve the above purposes, the present technology provides a siphon-type composite uf filtration component module as shown in Figure 1, including the millimeter-level (1) outer screen type protective housing and (4) inner grid-type membrane support cage, the micron-level (2) microfiltration layer and (3)activated carbon fiber adsorption layer and the nano-level (5) ultrafiltration layer. From outside to inside, each layer’s filtration nominal poresize is smaller. The microfiltration layer and the ultrafiltration layer are ultra-hydrophilic materials, the ultrafiltration membrane is a gradient sponge aperture structure with an internal aperture size larger than the outer aperture size, the mesh screen outer protective layer, the microfiltration layer, the carbon fiber adsorption layer, the mesh gate inner support layer and the ultrafiltration layer are closely integrated into a tube-like structure with siphon pressure difference. The end of the tubular structure is equipped with a water outlet port that only provides water from the ultrafiltration layer.

The Siphon Composite Gravity Filtration Module

The material of the outer and inner screen support may be one or more of PVC, ABS, PP or PE, and the average aperture size of the inner support layer of the grid type is between 1 and 20mm. here we select UPVC/OPVC cage with 1-2mm gap size.

The material of the microfiltration layer is ultra-hydrophilical PP cotton, the average aperture size of the microfiltration layer is between 2 to 200 micron. here we select pp cotton with pore size @15-20micron.

The carbon fiber adsorption layer is made up of antibacterial modified carbon fiber in diameter range from 1 to 100um, and the pore aperture of the carbon fiber adsorption layer is between 1 to 50 um, with a pore rate of 40 to 90%. Area ≧1300m2/g.

The ultrafiltration membrane filter layer may be polyfluoroethylene, polyurethane, polyether, polyvinyl chloride or poly-acrylic, the outer aperture size of the ultrafiltration layer is between 0.01 to 1.0 m, the ratio of the size of the inner aperture to the outer aperture size between 10:1 to 200:1, the pore rate is between 40 to 80%, Pure water flux is not less than 4000 L.m-2.h-1. here we select ultrafiltraion with pore size @ 50 nanometer.

The Beneficial Effects Of The Technology

(1) The aperture of the filtration structure from outside to inside is gradually reduced from millimeter, micron to nano-scale, forming a closely gradient transitional siphon type structure, and the water source is automatically driven by the siphon effect into the inside of the filtration structure, without external energy or electricity required, the water can be treated with multi-absorbed-filtered way.

(2) Optimize the design of water tank height, ratio of water level and filter diameter, in order to ensure the purification filtration efficiency and water flow rate , at the same time, to avoid to form a tight filter cake layer at the membrane surface, greatly reduce the equipment cleaning, maintenance frequency, improve the stability of the filter structure.

Reviews

There are no reviews yet.