Description

Membrane Bio Reacter process is combination of Membrane separation and biological technology. Water can permeate the tiny pore and activated sludge entrapped in tank, so it can greatly enhance the system’s ability to degrade pollutants. The cod bod can be greatly degradated and removal suspended solids, bacterial viruses (99.9%) etc. Thus Membrane Bio Reacter ensure a stable excellent water quality which can be reused for non-drinking purposes, such as car washing, gardening, flushing, cleaning, watering, irrigation etc.

MBR Advantage

- Permanently hydrophilic, excellent anti-oxidation

- High intensive strength, high anti-peeling strength

- Large flux, pure water flux up to 1000 l/m2·h; design flux 10-25 l/m2·h

- Fine filter precision, pore size @ 0.03 mm(b) or 1 mm(a)

- Excellent & stable permeate quality, turbidity close to zero

- Long lifespan for 5-8years

- Large installed filling area, small footprint

Application

- Domestic Sewage Treatment

- Plating Wastewater Treatment

- Municipal Wastewater Treatment

- Chemical Wastewater Treatment

- Industry Wastewater Treatment

- Food Wastewater Treatment

- Laundry Wastewater Treatment

- Oil field Wastewater Treatment

- Textile Wastewater Treatment

- Effluent Recycling

- Slaughter Wastewater Treatment

- Hospital Wastewater Treatment

| MODULE DATA | MBR-10 | MBR-20 | MBR-28 |

|---|---|---|---|

| Nominal Area (m2) | 10 | 20 | 28 |

| Dimensions (mml) | 1000*535*40 | 1800*535*40 1 600*630*50 |

2170*630*50 |

| Recommend Flow (m3/day) | 2-3.5 | 4-7 | 6-10 |

| Dry/Wet Weight (kg) | 9/18 | 18/35 | 26/50 |

Membrane Properties

| Membrane Material | Reinforced PVDF |

| Nominal Pore Size (µm) | o.o5 I o.1µm |

| Fiber Diameter | 2.6/1,2, 2.4/1.0, 2.0/0.9mm |

| Breaking Strength | >200 N |

| Processing Method | Embedded coating |

| Surface Properties | Non-Ionic & Hydrophilic |

| Flow Path | Outside-In |

Operation Maintainance

| TMP Range | -0.05 to 0.05 Mpa |

| Operating Temperature | 5~45°C |

| Operating pH Range | 7.0-9.0 (consider biological |

| Operation flux | 10-25 L/m2·h |

| Backwash flux | 30-60 L/m2·h |

| Max Cleaning Temperature | 40°C |

| Cleaning pH Range | 1.0-13.0 |

| Max. NaCIO Concentration | 5,000 ppm |

| Permeate Turbidity | < 0.5 NTU |

MBR-12, MBR-15, MBR-25, MBR35 and customized model are available

| CASSETTE MODULE | MBR1 00T | MBR200T | MBR300T |

|---|---|---|---|

| Quantity of MBR element | 1 7pcs*MBR20 | 36pcs * MBR20 | 36pcs * MBR28.5 |

| Total Filtering Area (m2) | 340 | 720 | 1026 |

| Cassette Size (mm) | 1 780*725*2000 | 1930*14 70*2000 | 1940*1470*2480 |

| Design Flow (m3/day) | 70-150 | 150-300 | 300-600 |

| Recommend Flow (m3/day) | 70-100 | 150-200 | 300-400 |

| Connection Size (mm) | 63 mm(7.l< water) 63 mm(“cair) |

90 mm(7.l < water) 63 mm(“cair) |

90 mm(7.l< water) 63 mm(“cair) |

Customized Cassette Module are preferred

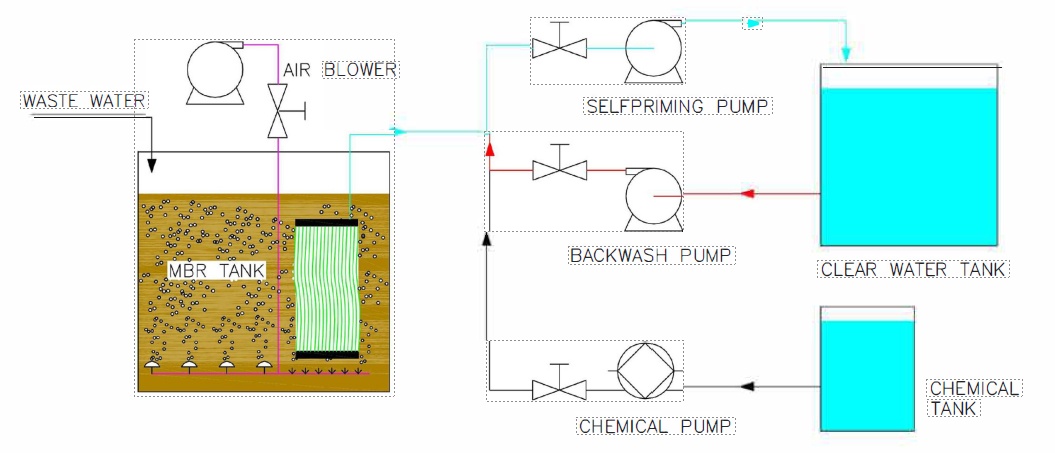

Typical MBR Process

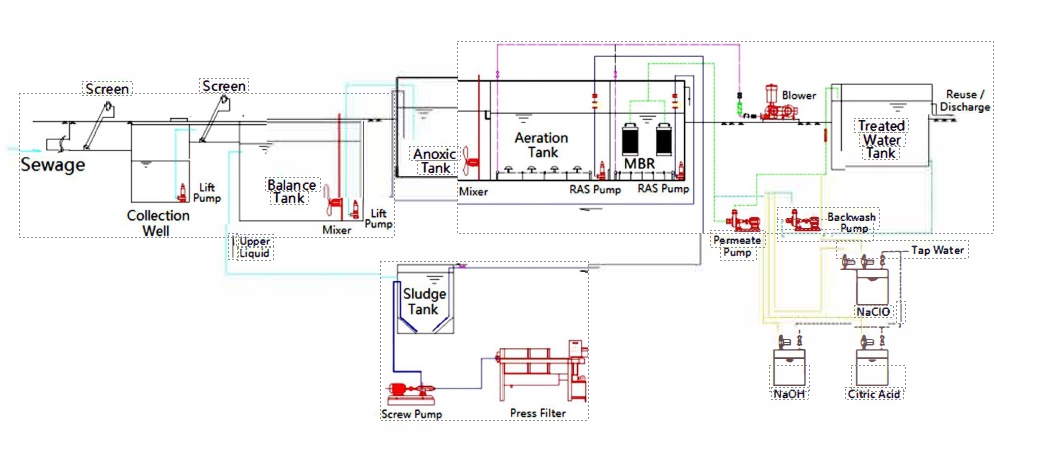

Typical Sewage Treatment Process

Reviews

There are no reviews yet.