Technology

The Technology relates to the solid type alloy PVDF hollow fiber membranes, especially to an ultra-hydrophilic gradient sponge micro-structure PVDF hollow fiber membrane, an ultra-high-strength, super-hydrophilic, ultra-high water flux, and ultra-high pollution resistance gradient PVDF hollow fiber Ultra Filtration membrane.

Basics of Ultra Filtration Membrane

Ultra-filtration water treatment technology has the characteristics of high efficiency and energy saving. , To some certain extent, the popularization and application coverage of membrane separation technology reflects the extent of energy use and environmental protection of a rustic and region. It’s also a guaranteed means for the sustainable development of society. Therefore, the strategic position of membrane separation technology is extremely prominent.

The key point to Ultra-filtration water treatment is that the microporous structure and surface properties of the membrane material. Scientists around the world proceed from the choice of materials and therefore the optimization of the membrane-making process so as to organize a membrane separation material with excellent performance.

Accessing a membrane has an honest practical value should depend upon the subsequent few points:

- High retention rate and high water permeability rate;

- Strong resistance to physical, chemical, and microbial attack;

- Flexible and sufficient mechanical strength;

- Resistant to heat

- Excellent anti-pollution;

- Good resistance to chlorine and other oxides;

- Long service life and withstand a wide selection of pH value;

- Low operating pressure

- Easy to store and transport;

- Convenient preparation and industrialized production;

- Dry and wet reversible.

Obtaining membrane separation materials with excellent separation selectivity and better permeability has always been the goal pursued by membrane scientists and engineers. Through research on hollow fiber membranes from the choice of membrane-forming materials, optimization of process parameters, surface post-treatment, and style of membrane modules in research project institutions everywhere the planet in recent decades, the general performance of hollow fiber ultra-filtration membranes and microfiltration membranes has been updated fully.

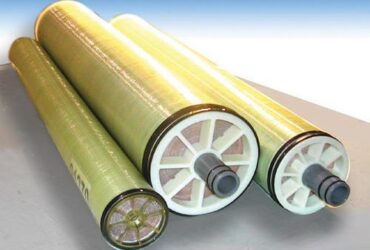

Recently, the high-end ultra-hydrophilic and excellent pore microstructure separation membranes are mainly produced by few international famous companies. Including XP series hydrophilic hollow fiber ultrafiltration membranes from DuPont -Dow, HYDRA cap series hydrophilic hollow fiber ultrafiltration membrane produced by Nitto/hydraulics, DICP series polyvinylidene fluoride hydrophilic ultrafiltration membrane from Toray. Targa series hollow ultrafiltration membrane produced by Koch and hydrophilic hollow fiber ultrafiltration membrane from SUEZ (GE). Therefore, these few international well-known brands firmly occupy the high-end market of ultra-filtration membranes.

In recent years, Chinese ultra-filtration and microfiltration membrane has also improved to a particular extent in terms of fabric types, membrane structure, and performance, etc. However, Chinese companies are still lacking a high-performance ultra / micro-membrane for water treatment with excellent comprehensive properties like super-hydrophilicity, high anti-pollution, high strength, high throughput, low membrane pressure, and long-term service stability. These high-end membranes still rely heavily on foreign brands. This example greatly limits Chinese membrane’s service lifespan and application fields.

How We Developed Ultra Filtration Membrane

Aiming at the shortcomings of existing technology, hydro blue has developed a high-performance ultrafiltration membrane with properties of gradient pore microstructure, super-hydrophilicity, high anti-pollution, high strength, high flux, low trans-membrane pressure, and long-term service stability. All comprehensive performance has reached the extent of those international well-known companies in Europe, the USA, and Japan.

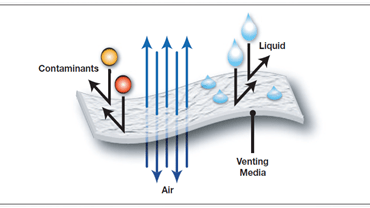

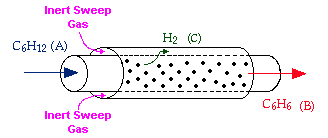

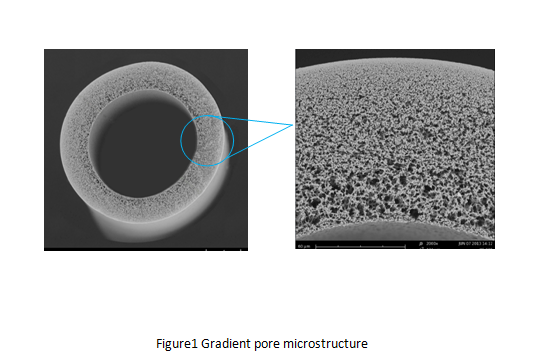

The micro nanobeads network structure (Figure1) is gradually increased from the outer surface to the inner surface along the radial section of the hollow fiber membrane. This network structure can significantly reduce the water permeation resistance, thereby significantly increasing water flux.

In this technology, the amphiphilic modified silicone material provides excellent and continuous hydrophilicity for the hollow fiber ultrafiltration membrane, thereby reducing the water permeability resistance and improving the membrane’s anti-fouling ability.