Description

MEMBRANE AERATED BIOFILM REACTOR

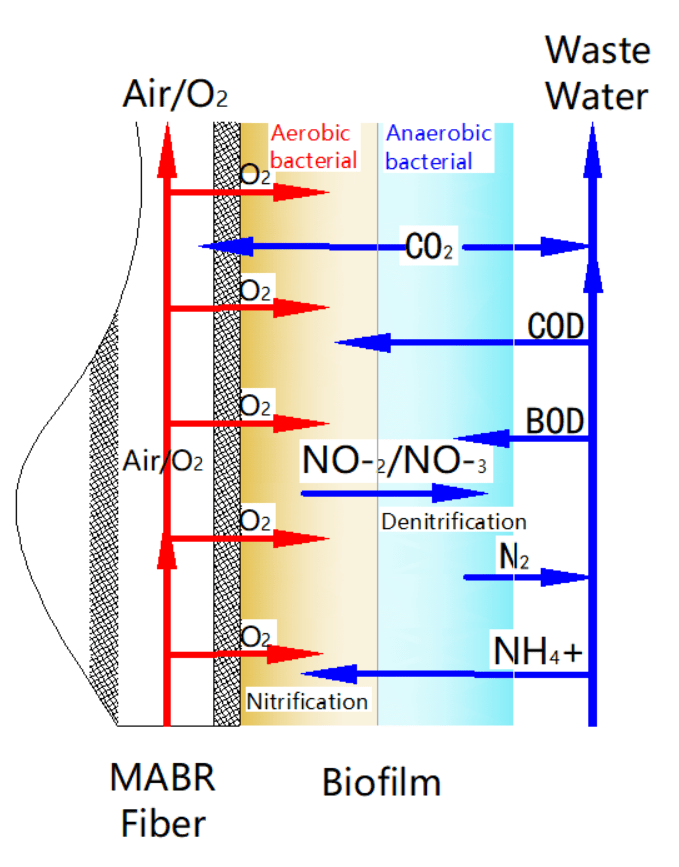

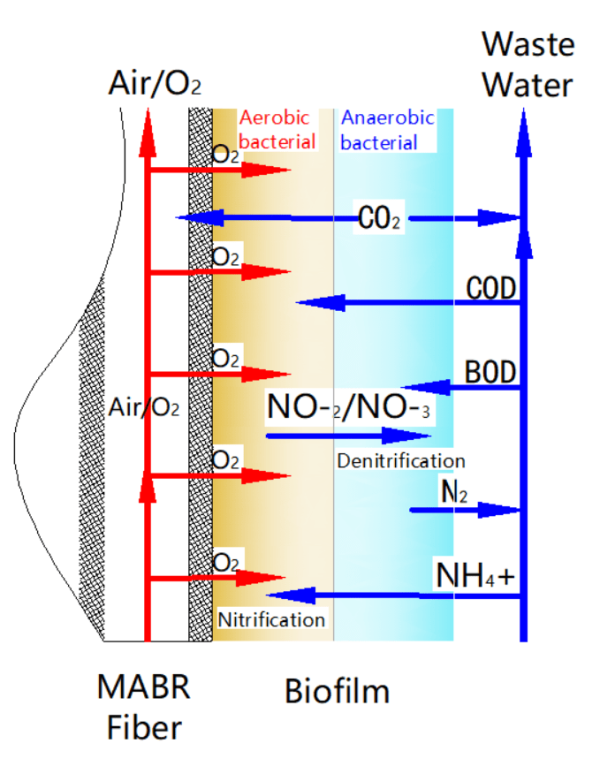

MABR (Membrane Aerated Biofilm Reactor) is a new wastewater treatment process with a combination of gas separation membrane technology and fixed biofilm. Oxygen is transferred in the form of oxygen molecules through the MABR membrane for bubble-free and efficient transport. The different layers of biofilms (aerobic nitrifying bacteria-anoxic denitrifying bacteria) are formed from the inside to outside on the membrane surface, which can achieve high-efficiency

simultaneous nitrification and denitrification in the same reactor, so as to achieve deep denitrification and denitrification of sewage. It is a new type of wastewater treatment process with high efficiency, low energy consumption, and low sludge yielding.

MABR Main Features:

- Molecular oxygen transmission, the oxygen utilization rate is 2-4 times that of traditional aeration;

2、Dense non-porous structure, no membrane clogging.

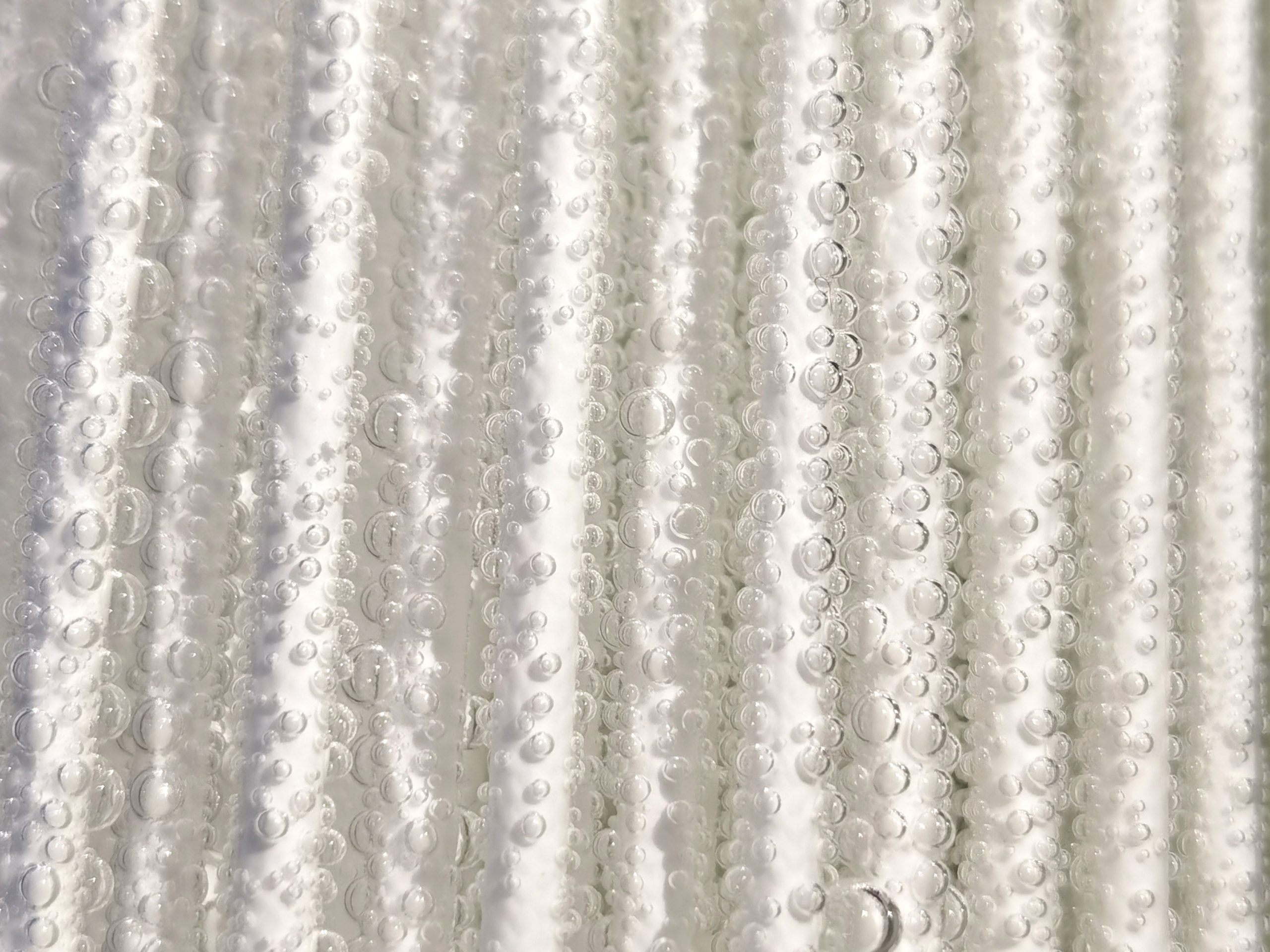

3、Bubbleless oxygen transfer, environment friendly;

4、Low-pressure less flow air supply, energy saving up to 50-70%;

5、TN removal is prioritized, carbon source addition is reduced

6、Simultaneous nitrification/denitrification, Minimize/Cancel RAS;

7、Sludge yielding reduce 30-50%

8、Operating temperature:-40℃~120℃,no location limit.

9、Modular Cassette, Small footprint

| Diffuser | Standard Aeration Efficiency |

| Coarse Bubble | 0.5~1.0 |

| Fine Bubble | 3.0~4.0 |

| Surface Aerator | 1.0 |

| Jet Aerator | 1.0 |

| MABR | 12.0~14.0 |

OXYGEN TRANSFER COMPARISON

BUBBLE DIFFUSER

High energy consumption

Large bubbles float up and release

Short contact time

Low oxygen utilization rate

MABR MOLECULAR DO

Low energy consumption

Molecular Oxygen Transfer

Oxygen directly supply to biofilm

High oxygen utilization rate

| NO. | Items | Unit | OX-MABR |

| 1 | Materials | – | Polymer |

| 2 | Pore size | μm | Dense and non-porous |

| 3 | Fiber Breaking Intensity | N | ≥150 |

| 4 | Burst Pressure | Kpa | ≥500 |

| 5 | Air permeability | L/㎡.h.bar | >0.1 |

| 6 | (OTR) Oxygen Transfer Rate | g O2/㎡.d | 6~20 |

| 7 | COD removal | g COD /㎡.d | 5~25 |

| 8 | Ammonia removal | g N/㎡.d | 1~3 |

| 9 | Processing Pressure | Kpa | 5~100 |

| 10 | Processing Airflow | L/㎡.h | 0.05~0.1 |

| 11 | Processing Temp | ℃ | -40~120℃ |

| 12 | Membrane Feature | – | Poreless structure bubbleless molecular

oxygen transfer;low energy saving SND;Biocompatibility;No Membrane clogging |

| 13 | Application | – | Anammox,Anoxic, Aerobic |

SPECIFICATION

| Model | Membrane Area | Length | Width | Thickness | Port |

| MABR-10 | 10m2 | 2000 | 535 | 45 | 32 |

| MABR-15 | 15m2 | 2000 | 535 | 45 | 32 |

| MABR-20 | 20m2 | 2000 | 630 | 50 | 25 |

| MABR-25 | 25m2 | 2000 | 630 | 50 | 25 |

| MABR-30 | 30m2 | 2300 | 630 | 50 | 25 |

MABR CASSETTE

| Model | Membrane Area | Length | Width | Height |

| MABR-480 | 480m2 | 2020 | 1450 | 2250 |

| MABR-1000 | 1000m2 | 2100 | 1450 | 2250 |

| MABR-1920 | 1920m2 | 2300 | 1450 | 2550 |

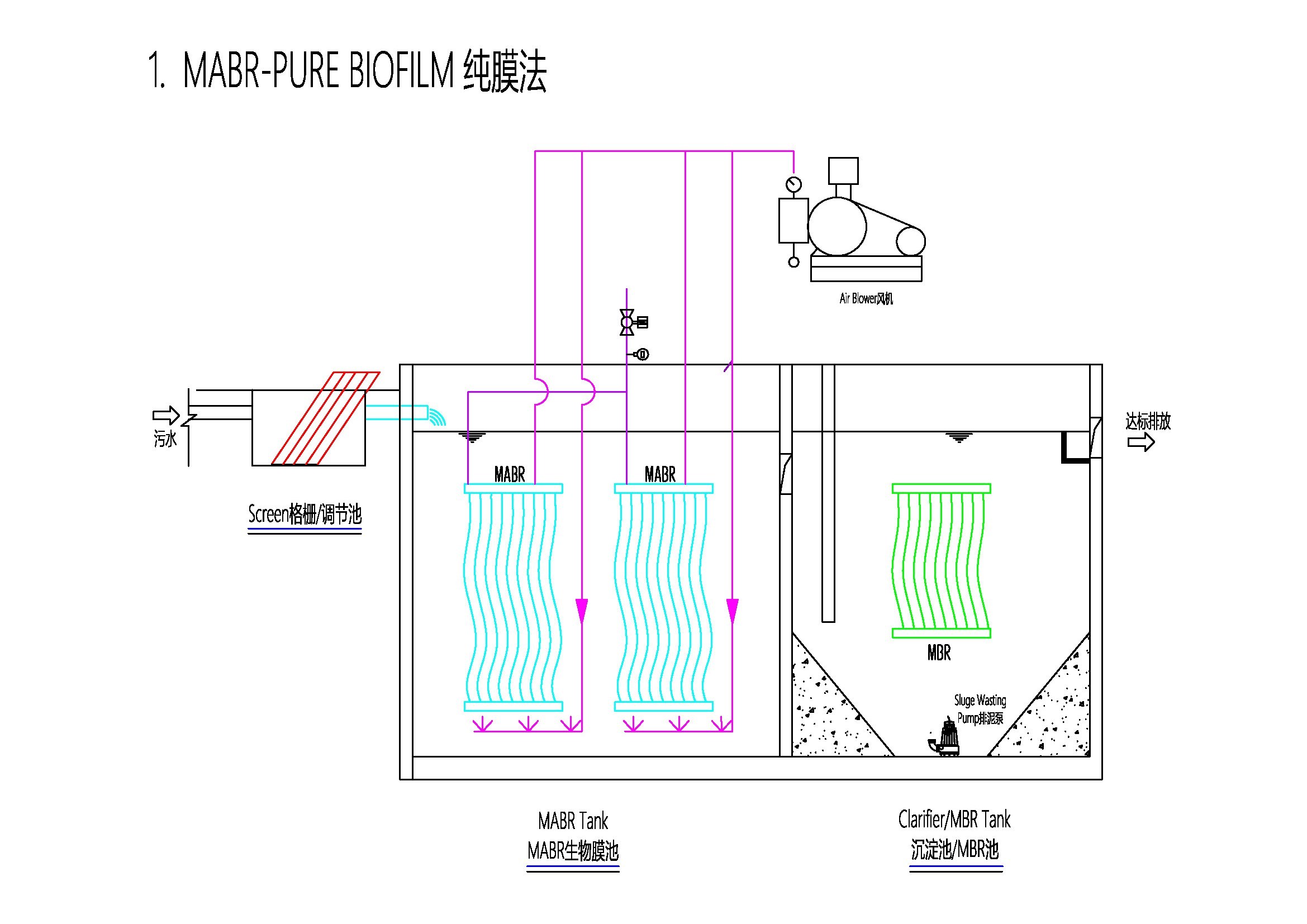

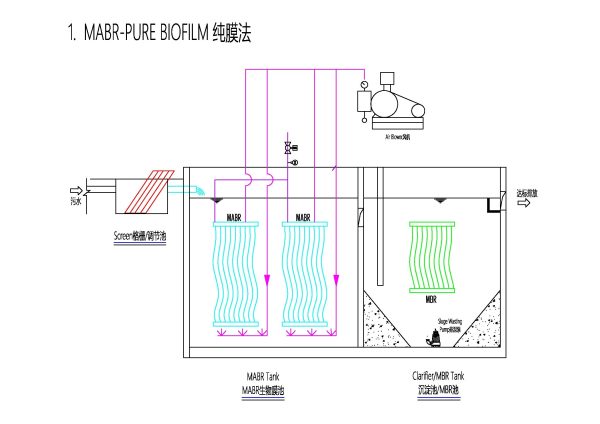

MABR PURE Biofilm

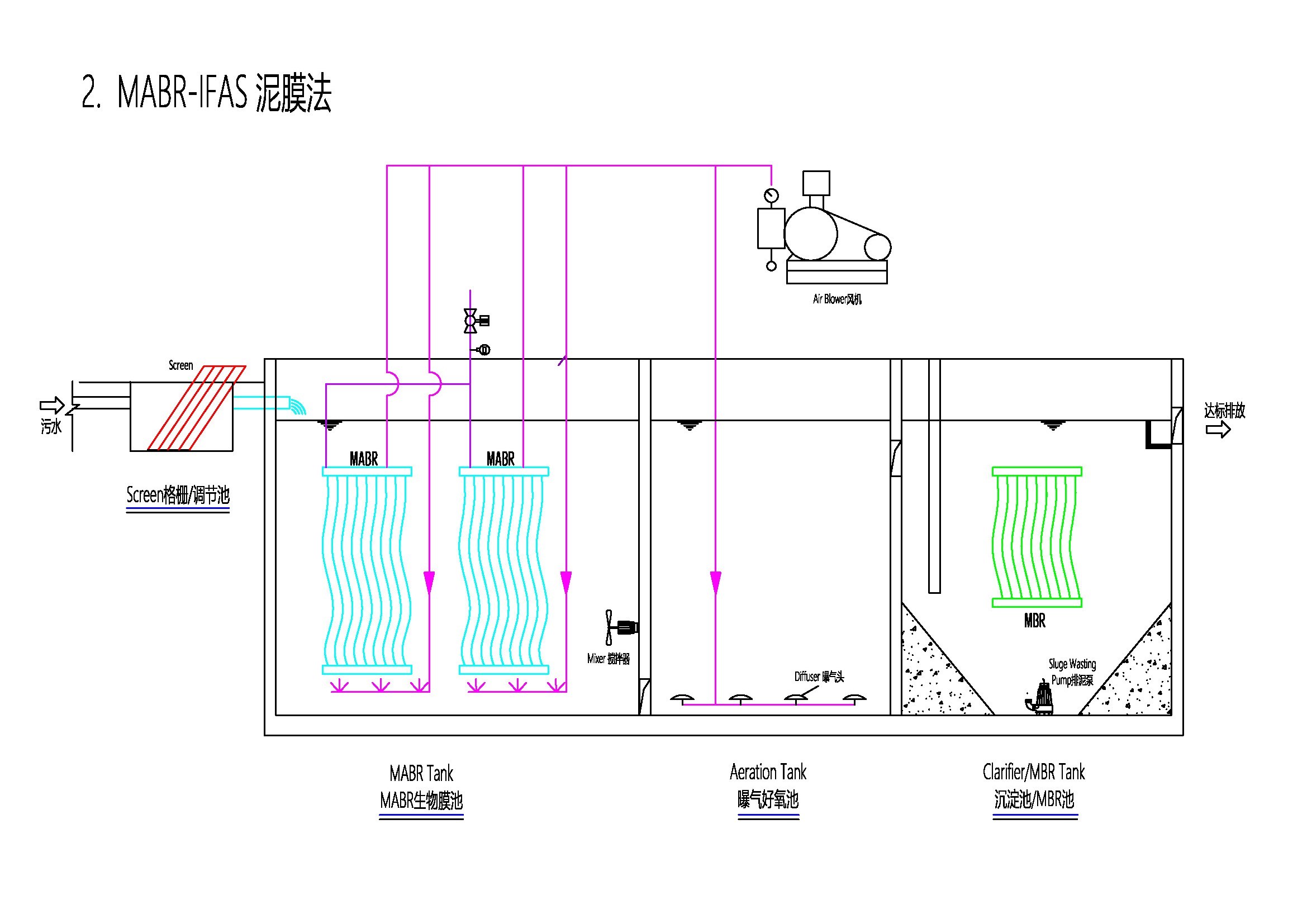

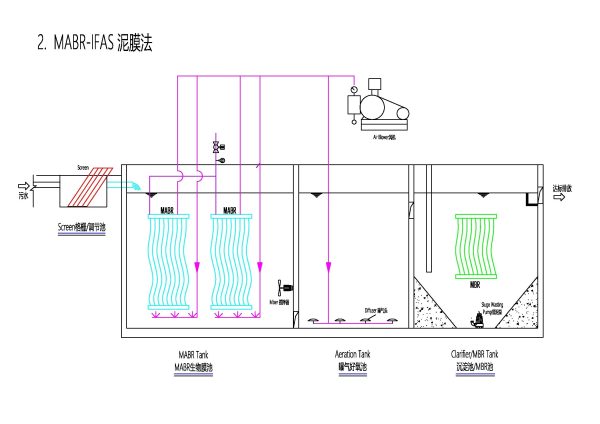

MABR IFAS

APPLICATION

- New construction/Expansion/Improvement of STP,WWTP;

- High Ammonia / Nitrogen WWTP;

- Aquaculture wastewater;

- WWTP in areas such as high altitude, Low temperature, Low pressure and Hypoxia

Reviews

There are no reviews yet.