Description

Description

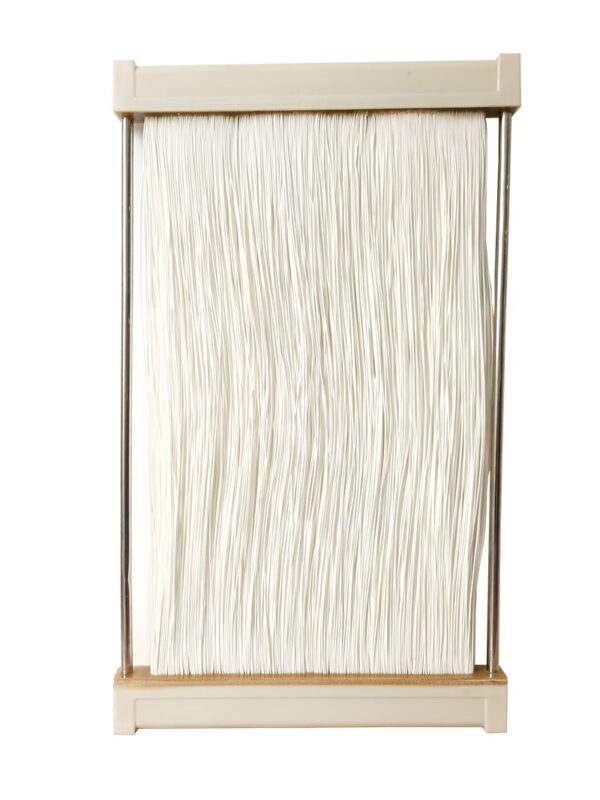

MBR Reactor provides a process that combines a membrane ultra/ micro filtration process and activated sludge process. It is used in place of the secondary sedimentation tank and sand filter used for tertiary treatment in the conventional activated sludge process. It features such as space saving, easy operation and high quality treated water which is reusable. In addition, advanced treatment of nitrogen and phosphorus removal can be achieved by anoxic / aerobic treatment. Mbr reactor combines membrane technology and biochemical reaction technology, through filtration and spoil disposal, to increase the concentration of the microorganism, enhancing the biochemical efficiency greatly, and degrading sewage. It succeeds in the treatment of domestic sewage, industrial wastewater of the fine chemicals, food wastewater, washes, pharmaceutical wastewater, hospital wastewater, landfill leachatedt-ro.

MBR Reactor system uses an advanced treatment technology that produces high quality reuse water at a competitive cost.

The technical characteristics of Membrane Bioreactor series:

1. The mechanical strength is very high, and the membrane filament is not easy to break off in the process of high strength aeration and chemical cleaning.

2. The chemical stability is very good and can be washed using the strong acid and alkali.

3. The cost performance is the best in the domestic same trade.

Sepecification:

| Module Data | MBR-10 | MBR-20 | MBR-30 |

| Nominal Area(m2) | 10 | 20 | 30 |

| Recommend Flow(m3/d) | 3.0~4.5 | 5.0~7.5 | 7.5~11 |

| Dimensions(mm) | 1000*535*40 800*630*42 | 1800*535*40 1500*630*42 | 2000*630*42 |

| Membrane Material | Reinforced –PVDF | ||

| Pore size(μm) | 0.1μm or 0.04μm | ||

| Fiber Diameter | 2.2/1.0mm or 2.6/1.2mm | ||

| Breaking Strength | > 200N | ||

| Flow Path | Outside-in | ||

| TMP Range | -0.05 to 0.05Mpa | ||

| Operating Temperature | 5-40℃ | ||

| Operating PH Range | 2.0-10.0 | ||

| Backwash Flux | 30-60L/m2.h | ||

| Permeate Turbidity | ≦0.5 NTU | ||

NOTE: MBR -5,MBR-12,MBR-25,MBR-35 and customized model are available.

Advantages:

1.Permanently hydrophilic modification, excellent Anti-oxidation.

2.High Intensive strength(≥200N),High Anti-peeling strength, no broken and peeling during normal operation, can withstand high frequent backwash.

3.Large Flux,pure water flux up to 1000L/m2.h, design flux 10-25L/m2.h

4.Fine filter precision,pore size@0.04um(B) or 0.1um(A), remove most bacteria, virus, microbe, particles, colloid, macro molecules organism etc.

5.Excellent&stable permeate quality, turbidity close to Zero

6.Long lifespan (3-7years), stable quality.

7.Large installed filling area,small footsprint.

Hot Tags: MBR reactor, China, manufacturers, suppliers, factory, customized, made in China

Reviews

There are no reviews yet.