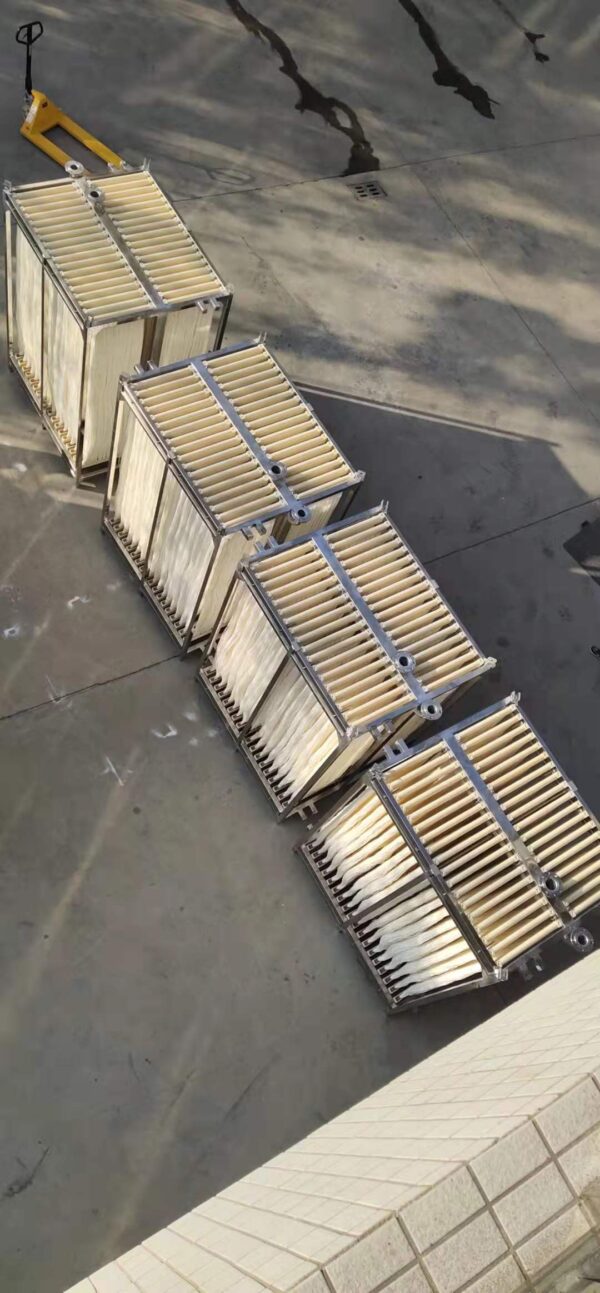

Description

The MBR process generally consists of a membrane separation module and a bioreactor, and the membrane assembly replaces the secondary sedimentation tank for solid-liquid separation. Since the membrane can trap all the biomass in the reactor, long sludge age and high suspended solids concentration can be obtained, which is beneficial to the growth of slow-growing nitrogen-fixing bacteria and nitrifying bacteria, and simultaneous nitrification and anti-inversion can be realized without aeration. Nitrification enhances the nitrification capacity of activated sludge, and membrane separation maintains a low FöM, making the excess sludge yield much less than the activated sludge process, and the system operation is more flexible and stable.

Process characteristics:

1.The concentration of activated sludge can reach 6000-12000mg/l, and the effect of removing organic matter is enhanced.

2. Effectively intercept small, slow-growing nitrifying bacteria, greatly improving ammonia nitrogen removal rate

3. Membrane filtration pore size reaches 0.05 microns, directly retaining bacteria, can be directly reused

4.Long sludge discharge period, low sludge yield, reducing sludge treatment costs

5. Saves the second settling tank and saves land; it can save 50% of the floor space compared with the traditional processing system.

6.low energy consumption, simple cleaning and low operating cost

Hot Tags: mbr waste water treatment, China, manufacturers, suppliers, factory, customized, made in China

Reviews

There are no reviews yet.